Resources

Field Reports

WSDOT Relines CMP Culvert, Designs Solution to Chronic Erosion

Abstract

On White Pass, Lewis County, WA, the Washington State Department of Transportation (WSDOT) designed a long term solution to a chronic erosion problem alongside US12. This field report presents an existing application where Snap-Tite was used to reline a culvert on a mountain pass characterized by dynamic weather conditions and steep slopes. Traditional repairs relied on continual maintenance to sustain a safe roadway.

Introduction

Alongside US12 near the summit of White Pass an existing 36-inch corrugated metal pipe (CMP) culvert conveyed water under the traveled lanes from an upstream gully and ditch. The outlet of the culvert was originally designed at ground level with a conventional rock riprap energy dissipater, which over time was washed down to a creek at the toe of the slope. The steep slope limited certain designs due to constructability issues. Using Snap-Tite increased both the speed and ease of installation and provided a long-term solution to the problem.

The Problem

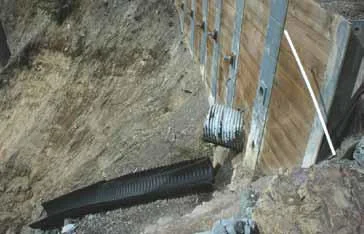

The outlet of the old culvert had a significant amount of erosion that over time lowered the ground-line by more than three feet. This exposed the bottom of a soldier pile wall allowing backfill material to escape below the lagging, which compromised the stability of the roadway.

The Solution Applied

Grey Langemo and Bob Boyes of Grecor-LLC, the Snap-Tite representatives in Olympia, WA, worked with Casey Kramer, P.E. and Jay Christianson from the Headquarters Hydraulics Office for the WSDOT to find a solution. The collaboration resulted in the decision to use 28-inch Snap-Tite high-density polyethylene (HDPE) pipe to slip-line into the existing 36-inch crushed CMP. In addition, a 36-inch HDPE drainage basin served as a transition between the slip-lined and down-slope pipe. Finally, a 24-inch Snap-Tite down-slope pipe was used and anchored with cables to H-Piles. The design used a unique streamlined anchoring system consisting of three-fourths inch cable with customized pipe clamps to reduce drag forces on the down-slope pipe from snow, ice and plowing activities.

The design ultimately allowed for safe delivery of water under the roadway and eliminated erosion at the face of the wall. The project also minimized the amount of sediment entering the stream at the toe of the slope and allowed for easy maintenance access.

Snap-Tite:

- Meets AASHTO Standard M326 for rehabilitating culverts.

- Offers flexibility for insertion into misaligned concrete or rusted and deteriorated CMP.

- Offers a safe method for installers and does not require traffic control.

- Tough but lightweight, the Snap-Tite joint makes a solid water-tight mechanical connection that can be pushed or pulled.

Generally, as with any engineered system, time and usage are needed to develop acceptance. We are pleased Snap-Tite has been well received by numerous highway departments coast to coast. We attribute this to the Snap-Tite system’s overall installation flexibility and its consistently successful results.