HDPE Fusion Equipment

McElroy Optimized Cooling

Utilize McElroy’s proprietary DataLogger® technology to minimize cool time and optimize project productivity.

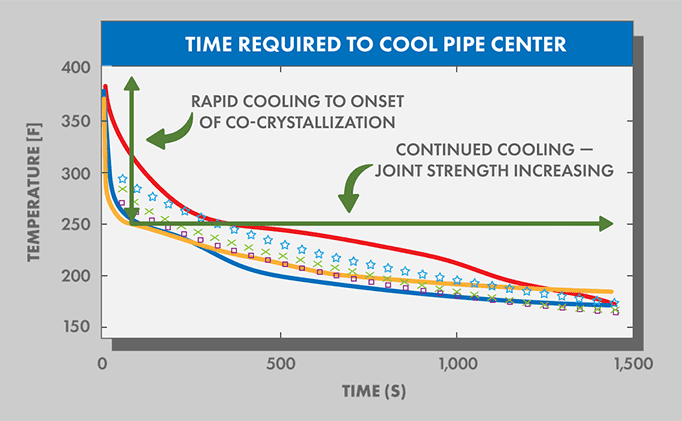

Cooling is the longest step in the fusion process. McElroy's Optimized Cooling™ is a proprietary, patent-pending algorithm designed to decrease cooling time within ASTM standards for increased jobsite productivity.

ASTM F2620 compliant.

Optimized Cooling™ technology uses McElroy’s advanced DataLogger® software to calculate, in real time, the most appropriate cool times based on material properties, environmental conditions and other factors so you can move on to the next joint at exactly the right time.

In developing this breakthrough technology, McElroy partnered with the University of Tulsa to test hundreds of fusion joints, analyzing thousands of data points and modeling computational fluid dynamics to understand core pipe temperatures for compliance with ASTM F2620-19 Note 10 and help assure safe handling.

Have Questions?

Visit McElroy's Optimized Cooling™ webpage for more details and to learn more about their proprietary cooling process.

Access our deep HDPE fusion resources

Posts

How to Choose the Right McElroy Fusion Machine for Your HDPE Project

Choosing the right fusion machine can make or break your HDPE installation. The right McElroy equipment improves joint integrity, speeds up production, and reduces field downtime. From small-diameter service lines to 65-inch pressure mains, ISCO’ helps contractors and utilities select the fusion equipment that matches their pipe size, application, and jobsite conditions—so every weld is strong, traceable, and built to last.

Field Reports

Putting the Squeeze on HDPE Repairs

The Footage Tools C2400 helped ISCO and partners complete a first-of-its-kind repair on a 24-inch HDPE water pipeline near Midland, TX. By safely shutting off flow without damaging the pipe, the tool enabled a faster, more efficient repair that saved time and money.

Posts

What is HDPE Fusion? A Complete Guide to Thermoplastic Pipe Joining

Fusion is the process of joining thermoplastic pipe—like HDPE, MDPE, and polypropylene—into a seamless, leak-free system using heat and pressure. Learn how it works and why it’s the gold standard for long-lasting infrastructure.