Resources

Field Reports

Read case studies of HDPE solutions for real-world problems across a wide range of applications.

Spirolite HDPE Culvert Reline Beneath Interstate

Read about the remarkable engineering feat of replacing a 280-foot segment within a 144” culvert crossing beneath busy Interstate 65 in Indiana. This project seamlessly installed 120” Spirolite High-Density Polyethylene (HDPE) pipe, upholding uninterrupted traffic flow. With ingenious “Bell and Spigot” connections, the lightweight Spirolite pipes were efficiently assembled and pushed into the existing culvert. The project’s success not only reflects the innovation of HDPE profile wall technology but also demonstrates its pivotal role in safeguarding local streams crucial to the farming community and the surrounding ecosystem. The installation, completed in under two days, stands as a testament to engineering excellence and proactive environmental stewardship.

Large-Diameter HDPE Pipe Solution for Sewer Replacement in Greenwood, SC

Greenwood, SC upgraded its sewer system with large-diameter HDPE profile pipe. Learn how ISCO’s Spirolite can offer a durable, leak-free solution for your next sewer project.

Overcoming Environmental Challenges with HDPE Pipeline Solution

King County Wastewater Treatment Division (WTD) in Washington addressed environmental challenges and an overwhelmed wastewater system with a complex project that utilized HDPE pipeline solution. Read about the project’s planning, construction, and installation, and how ISCO stepped in to provide a long-term solution that meets the needs of the community while supporting clean water and a healthy habitat.

Culvert Rehabilitation Using Spirolite™ HDPE Pipe System to Solve a Rusty Problem

ISCO utilized Spirolite HDPE pipe system to rehabilitate a pair of corroded metal culverts beneath State Highway 37 in Indiana. The slip-lining process offered a cost-effective and non-disruptive solution, which was essential due to the culverts’ proximity to a major interstate and deep subterranean location.

HDPE Piping Solution for AmerenUE Callaway Nuclear Plant

ISCO Industries worked closely with AmerenUE to provide HDPE solutions to two critical carbon steel piping systems at the Callaway nuclear plant in Missouri. The solutions provided safe and reliable operations at the plant, providing clean and affordable electricity to hundreds of thousands of households.

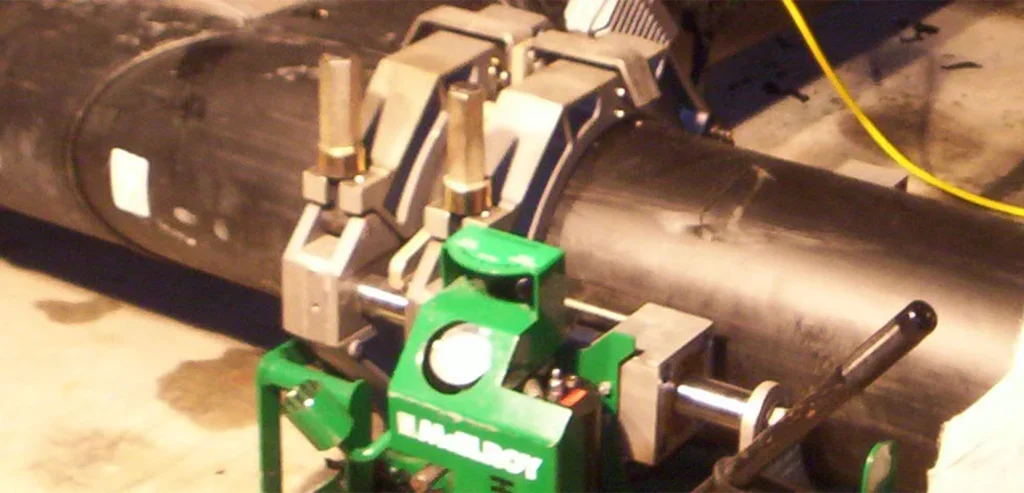

McElroy DynaMc 412 Fusion Machine Used in Tight Space

Learn how ISCO’s compact and lightweight McElroy DynaMc 412 hand pump fusion unit was used to replace a 12-inch corroded steel pipe inside a potable water storage tank in San Clemente, CA. The limited access to the reservoir presented a challenge, but the innovative solution provided by ISCO’s total piping solutions made the project a success, completing the job on-time and within budget.