Resources

Blog

- By ISCO

- Tuesday, 17 June 2025

- Applications:

What is HDPE Fusion? A Complete Guide to Thermoplastic Pipe Joining

What is Fusion?

Fusion is a proven process used to join thermoplastic pipe—such as HDPE, MDPE, and polypropylene—into a single, seamless, leak-free system. It works by heating the pipe ends to a precise temperature and then pressing them together under controlled force. As the material cools, the two ends bond at the molecular level, forming one continuous piece of pipe.

Why it matters: This heat fusion process eliminates the need for mechanical joints, couplings, or gaskets, which are often points of failure in legacy piping systems. It’s widely used in critical infrastructure because it creates long-lasting, corrosion-resistant pipelines with minimal maintenance.

How Does Fusion Work?

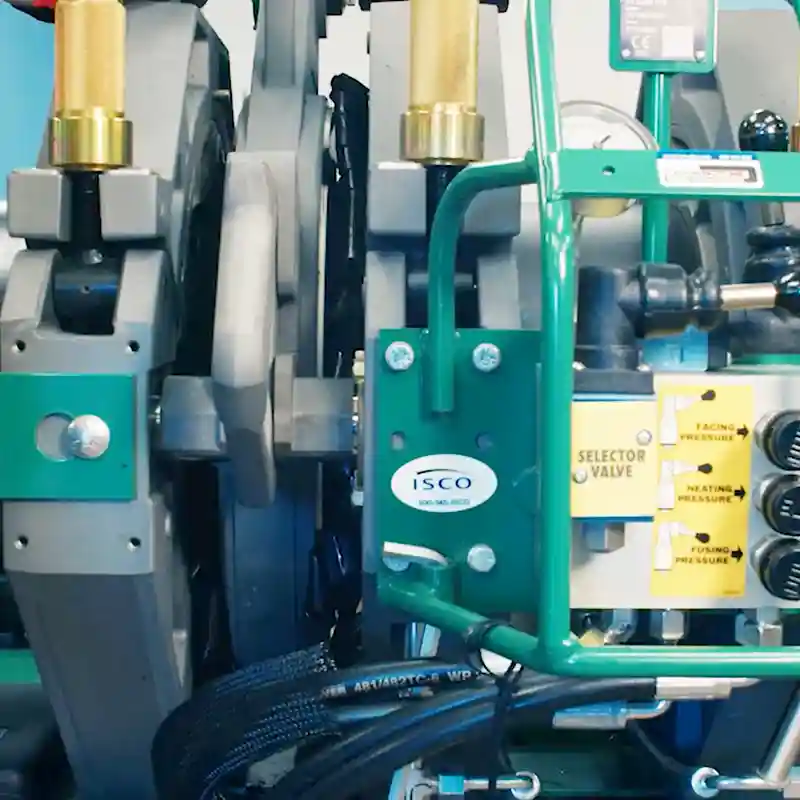

There are a few core steps involved in butt fusion, the most common method for joining thermoplastic pipe. Each step is carried out using fusion equipment designed to heat, align, and join the pipe ends with precision. When done correctly, the result is a monolithic pipeline system—strong, seamless, and built to perform in demanding environments.

1. Clamping the Pipe

Pipes are secured and aligned in a fusion machine to ensure even pressure and clean mating.

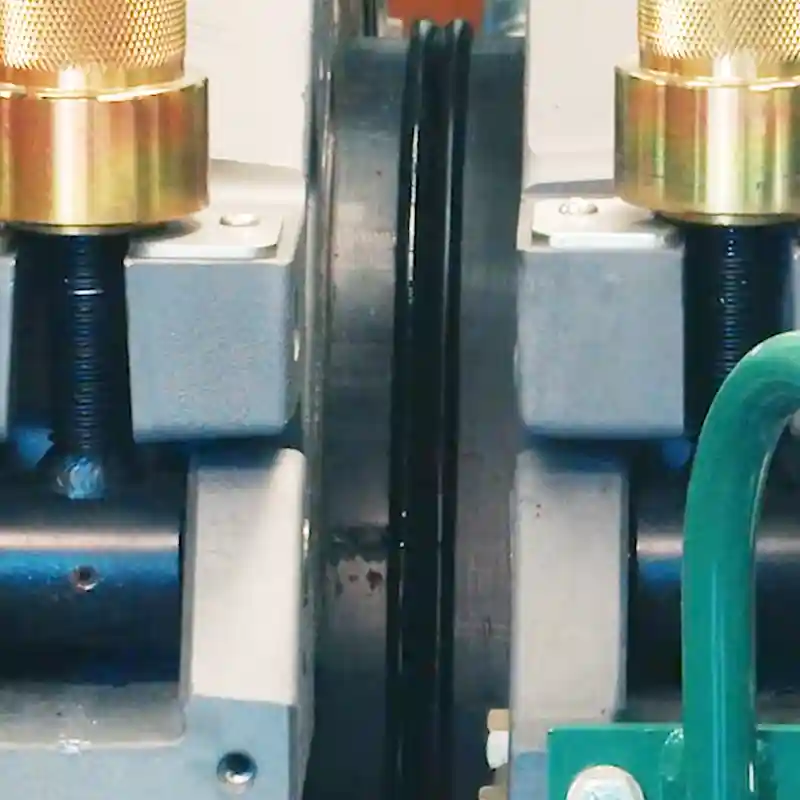

2. Facing the Pipe

A facing tool shaves the pipe ends until they’re smooth, even, and perfectly perpendicular.

Why Choose a Fusible Pipe System?

Where is HDPE Fusion Used?

Fusible pipe systems like HDPE are widely used across various end markets and applications for its durability, flexibility, and corrosion and chemical resistance. Here’s a short list of common HDPE pipe applications:

- Municipal water and sewer systems

- Industrial process piping

- Landfills and leachate collection

- Data center cooling infrastructure

- Mining operations

- Natural gas and oilfield gathering lines

FAQ: HDPE Fusion

Q: What makes HDPE fusion better than legacy pipe joining methods?

A: The fusion of thermoplastic pipe eliminates mechanical joints, reduces risk of leaks, and minimizes long-term maintenance.

Q: Is pipe fusion possible in the field?

A: Yes. With the right fusion equipment, HDPE fusion is commonly performed on the jobsite—even in remote or harsh environments.

Q: What pipe sizes can be fused?

A: HDPE pipe from ½” to 130″+ diameter can be fused using the appropriate tools.

Q: What types of fusion equipment are used for HDPE pipe?

A: HDPE pipe fusion uses equipment like butt fusion machines, electrofusion processors, facing tools, and heating plates. These machines align, heat, and press the pipe ends together with controlled force to create strong, leak-free joints. Equipment type varies based on pipe size, jobsite conditions, and fusion method. Explore HDPE Fusion Equipment →

Want Help With Fusion? Let ISCO Support Your Project

With the largest HDPE fusion fleet in North America and decades of hands-on experience, ISCO supports your project from specification to execution. We rent, sell new and used, and service fusion equipment. We also offer on-site support to ensure every joint is strong, clean, and done right.